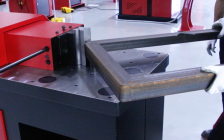

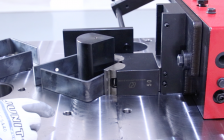

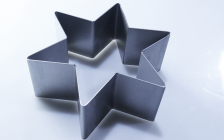

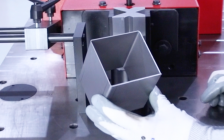

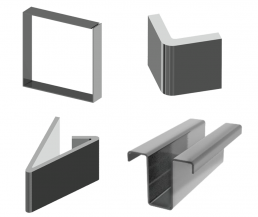

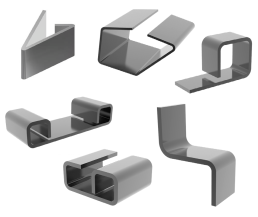

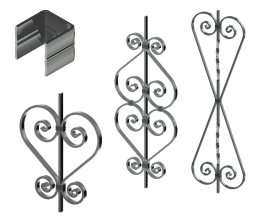

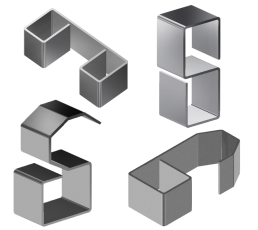

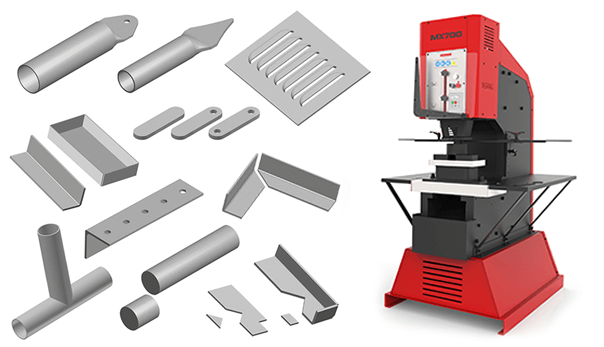

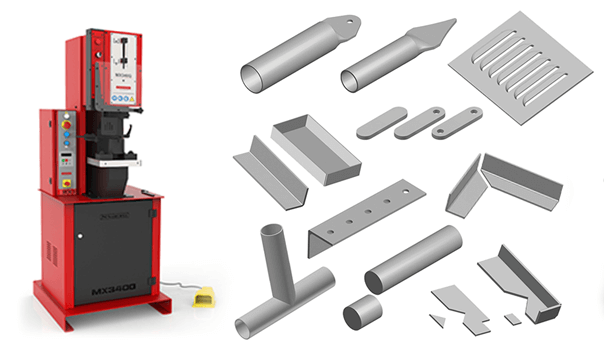

Samples of jobs done with Horizontal Press Brake PP200CNC

BRAND NEW 20 ton Nargesa PP200CNC Horizontal Press Brake. Includes CNC Control Panel with the latest 4.0 technology, for a more comfortable and accurate regulation. It allows us to carry out different operations such as bending, folding, cutting, cold shaping, expand and reduce tubes, notching, inlaying, assemble... with maximum precision and speed

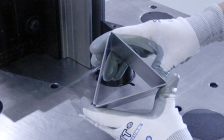

The versatility of the best Horizontal Hydraulic Press Machine Nargesa PP200CNC makes it possible for us to make a great deal of forging parts and all kinds of operations in all kinds of materials: pipe, flat bar, several profiles, rods... Folding operations with wrought iron machines permit to completely bend the parts or pieces unlike conventional flat bar section bending machines. Stretching and reducing pipes on the ends in order to make parts that fit or weld later. Cutting, piercing and punching flat bars or metal sheets turn this horizontal bending press into a punching shears machine. Many workshops use these presses to stretch and form different kinds of profiles. It is also a solution to bend different profiles at different radius and keeping the ends straight, like when manufacturing handles and flanges. Pipe notching to assemble to another one at 90º. Cold forge uses horizontal presses to make and form different shapes of balosters...

Its robustness, versatility, easy handling and 4.0 Technology are just four of the best features our hydraulic horizontal bending machine hasworking processes.

All Nargesa’s Products are according to CE regulations for the manufacturing of industrial machinery.

Technical features

Horizontal Bending Press Brake PP200CNC has been manufactured in a 60mm thick welded steel monoblock, stabilized and mechanized. Its robustness, versatility and easy handling are just three of the best features our hydraulic horizontal bending machine has.

ADVANTAGES

- NEW Control Panel: Very intuitive and easy to handle, with the latest 4.0 technology and a more comfortable and accurate regulation.

- The new ECO mode of our latest products saves energy and contributes to the conservation of the environment.

Nowadays, we know the remarkable importance of saving energy. This is the main reason why our new machinery incorporates an "ECO mode" that automatically disconnects the electrical parts that generate greater energy consumption if a period of inactivity is detected. Thus, when it is necessary to restart the operation, all you have to do is press the pedal to continue working.

We strongly believe that this feature is a core point both for the savings of our clients and for the sustainability of our planet, since we are a company very committed to the environment. - Quick start-up: The machine is shipped fully assembled, it is only required to connect it to the electrical supply and run it.

- Versatility: Nargesa PP200 has a catalog with a great deal of optional tooling. (See at the bottom of the page in optional tooling and sample video).

- Easy fabrication of tooling: The customer himself or any toolmaker can manufacture dies and punches.

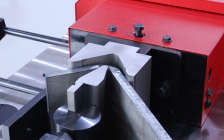

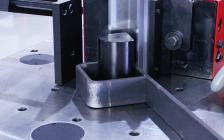

- Folding operation with no risk of damaging the punches and dies with thick materials unlike conventional press brakes.

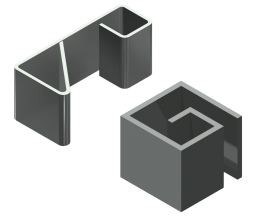

- Folding flat bars and sheets into completely close shapes. Conception of this horizontal bending press brake allows to make folding operations impossible to be carried out on a conventional press brake.

- Fast tool change, punches and dies: This change does not take more than 30 seconds most of the times.

STANDARD TOOLING: Horizontal press brake PP200 includes the complete 4V’s folding die. (See bottom of the page in standard accessories).

Technical Features of the Horizontal Hydraulic Press Machine

- Working force: 20Ton.(200KN)

- Working speed: 9.8mm/s

- Return speed: 35mm/s

- Max stroke: 245mm

- Repeatability: 0.05mm

- "ECO mode" Start/Stop in period of inactivity.

- ESA S625 CNC control

- Technology 4.0.

- Storage of up to 10,000 programs.

- Programming of 50 different angles in the same piece.

- Programming in mm or inches.

- Library of dies and punches.

- Programming in more than 20 languages.

- Automatic control of angle to fold in degrees.

- Manual or automatic operating mode.

- Automatic springback correction.

- Counter of pieces.

- Diagnosis of alarms on the screen.

- Automatic warning of preventive maintenance.

- Remote connection included.

- 7" color touch screen

- Safety Double acting hold pedal.

- Mechanically Guided Piston.

- Pressure regulator.

- Tooling support table: 600x1170 mm.

- Working height: 950 mm.

- Engine power: 2.2 KW/3 HP a 1400 r.p.m.

- Electric Tension: 230/400 V three-phased.

- Intensity: 9/5 A.

- Hydraulic pressure: 50 a 215 Kg/cm2.

- Hydraulic pump: 7,5 litres/minute.

- Tank Capacity: 27 litres.

- Dies support shelf included.

- Palletized lower bench to easily transport the machine up to its working or storage site.

- The machine is sent completetly assembled.

- Packing included: Wooden pallet NIMF15 and three layer cardboard apt for suitable for sea freight.

All our products are manufactured in our facilities in Spain. Hydraulic and electrical components are all standard from the best leading European trademarks with technical support all over the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato, etc...

Optional accesories for Horizontal Hydraulic Press Brake PP200CNC

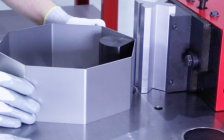

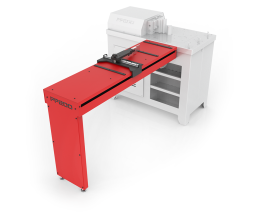

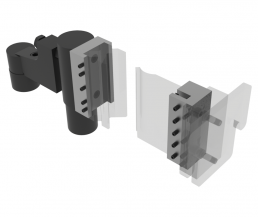

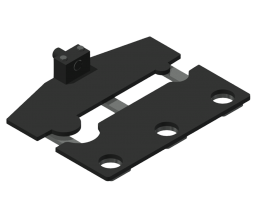

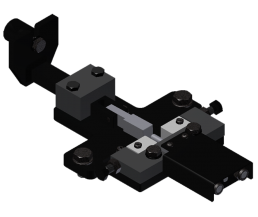

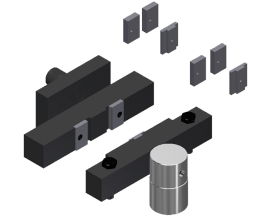

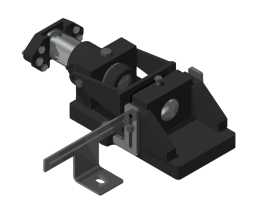

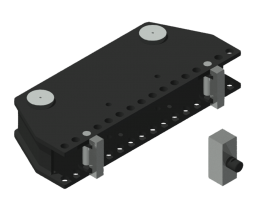

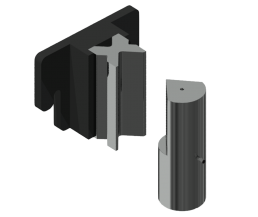

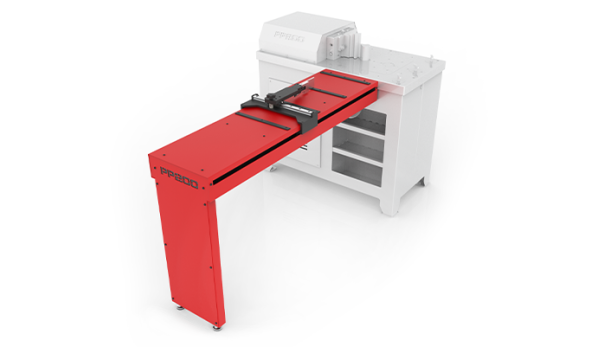

Automated Gauge for the PP200CNC Press Brake

The ALL-NEW Automated Gauge for the PP200CNC Press Brake is an accessory designed and manufactured to get the greatest performance out of the Nargesa Horizontal Hydraulic Press Brake PP200CNC. This Automated Gauge for the Nargesa PP200 CNC horizontal Press Brake offers increased productivity and a reduction in the time it takes for positioning in the various work cycles. This innovative design provides the capability of automatically positioning the X-axis during different operations programmed and calculated using the ESA S625 CNC control. This approach significantly helps enhance the operating features as well as the quality of work done with this machine.

The Automated Gauge for the PP200CNC allows single or serial parts to be produced with greater accuracy, speed and repeatability compared to the previous manual system.

REF: 140-16-01-50000

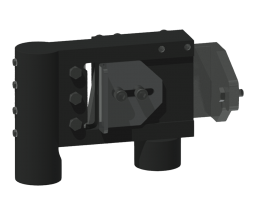

Flat bar cutting tooling 100x10mm PP200

Flat bar and metal sheet cutting die up to 100mm through a maximum thickness of 10mm in mild steel.

REF:140-16-01-00014

MAX. CUTTING LENGTH: 100mm

MAX. CUTTING THICKNESS: 10mm

WEIGHT: 23 Kg

Optional tooling.

Promecampunch holder PP200

Punch holder for all kind of punches for Promecam bending or folding press.

REF:140-16-01-00023

MAX. FOLDING LENGTH: 161mm

L LENGTH: 276 mm

Compatible with any Promecam punch.

WEIGHT: 14Kg

Optional tooling

Download (1.17 MB)

Inverted Promecam-holder PP200

Punch holder for all kind of punches for Promecam bending or folding press with inverted position.

REF: 140-16-01-00039

MAX. FOLDING LENGTH: 161mm

Compatible with any Promecam punch.

WEIGHT: 19,8 Kg.

Optional tooling

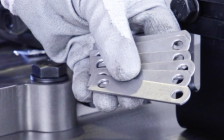

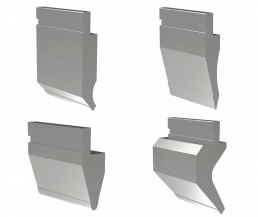

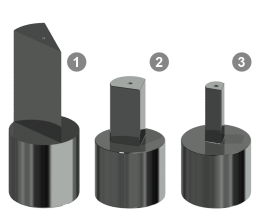

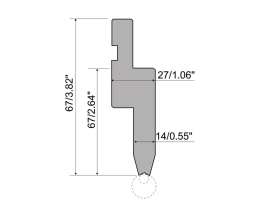

Promecam punches PP200

Promecam punches of different shapes to bend and manufacture complex part. There are a lot more shapes, please consult the manufacturer.

Nº1 Punch Promecam PS.135.85.R08 PP200

REF: 140-16-01-00030

FOLDING LENGTH: 161mm

WEIGHT: 3,2 Kg.

Nº2 Punch Promecam PS.134.30.R08 PP200

REF: 140-16-01-00032

FOLDING LENGTH: 161mm

WEIGHT: 2,7Kg.

Nº3 Punch Promecam P.95.35.R5 PP200

REF: 140-16-01-00031

FOLDING LENGTH: 161mm

WEIGHT: 2,3Kg.

Nº4 Punch Promecam PK.135.85.R08 PP200

REF:140-16-01-00038

FOLDING LENGTH: 161mm

WEIGHT: 4,4Kg.

Optional tooling.

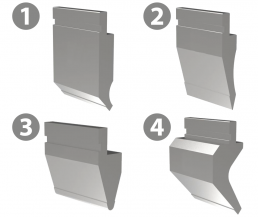

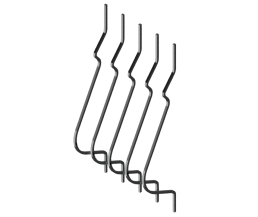

Special punches PP200

Folding punches to bend special pieces of small sizes or folded up to 30º.

Nº1 Folding Punch D70 30º P.70.30.R1,5

REF: 140-16-01-00025

MAX FOLDING LENGTH: 100mm

PUNCH DEGREES: 30º

PUNCH DIAMETER: 70mm

Nº2 Folding Punch D40 80º P.40.80.R1

REF: 140-16-01-00026

MAX. FOLDING LENGTH: 60mm

PUNCH DEGREES: 80º

PUNCH DIAMETER: 40mm

Nº3 Folding Punch D22 80º P.22.80.R1

REF: 140-16-01-00027

MAX. FOLDING LENGTH: 60mm

PUNCH DEGREES: 80º

PUNCH DIAMETER: 22mm

WEIGHT: 3Kg each unit approximately.

Optional tooling.

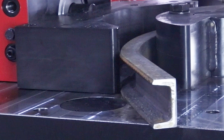

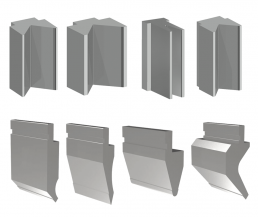

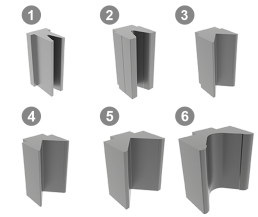

Dies to fold thick metal sheet PP200

Promecam dies of diferent openings to fold sheets, flat bars or thicker plate sections up to 15mm. in order to fold even thicker sizes, ask the manufacture.

Nº1 Folding die T80.25.35

REF: 140-16-01-00036

FOLDING LENGTH: 161mm Max. 35º

V25: From 1,5 to 5 mm sheet

WEIGHT: 4Kg.

Nº2 Folding die M80.45.40

REF: 140-16-01-00041

FOLDING LENGTH: 161mm Max. 45º

V40: From 3 to 8mm sheet

WEIGHT: 6,2Kg.

Nº3 Folding die M75.85.63

REF: 140-16-01-00033

FOLDING LENGTH: 161mm Max. 85º

V63: From 5 to 10mm sheet

WEIGHT: 5Kg.

Nº4 Folding die M80.85.80

REF: 140-16-01-00034

FOLDING LENGTH: 161mm Max. 85º

V80: From 6 to 12mm sheet

WEIGHT: 6Kg.

Nº5 Folding die M95.80.100

REF: 140-16-01-00035

FOLDING LENGTN: 161mm Max. 80º

V100: From 8 to 15mm sheet

WEIGHT: 9Kg.

Nº6 Folding die MK103.80.125

REF: 140-16-01-00040

FOLDING LENGTN: 161mm Max. 80º

V125: From 12 to 20mm sheet

WEIGHT: 12,4Kg.

Optional tooling.

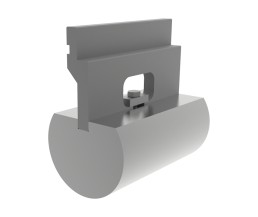

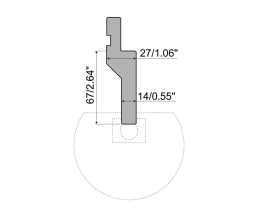

Small radii holder PU.67.14-S

European style R1 bending tool holder. (For radii from 3 to 7,5 mm)

REF: 140-16-01-00042

Folding length: 161 mm

Weight: 2 Kg.

Optional tooling

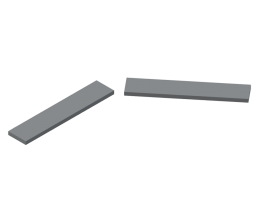

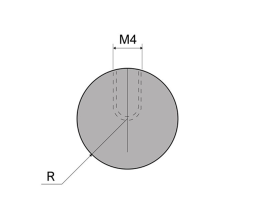

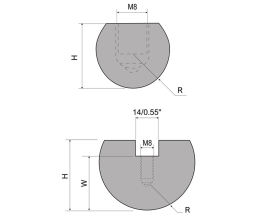

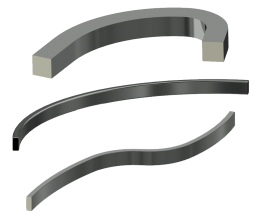

Radius elements for small radii holders PU.67.14-S

Radius elements to fold. Made of C45, a high quality, medium grade steel, with constant mechanical properties and good external chrome resistance.

Maximum capacity: 400kN/m.

Tonnage: 400 kN/m max.

For its use it requires the PU.67.14-S Small radius holder.

Please refer to the following radius chart:

Download (133.65 KB)

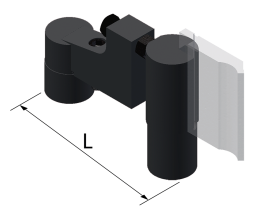

Big radii holder PU.67.14

European style R1 bending tool holder. (For radii from 8 to 50 mm)

REF: 140-16-01-00043

Folding length: 161 mm

Weight: 1,80 Kg.

Optional tooling

Radius elements for large radii holders PU.67.14

Radius elements to fold. Made of C45, a high quality, medium grade steel, with constant mechanical properties and good external chrome resistance.

Tonnage: 800 kN/m max.

For its use it requires the PU.67.14 large radius holder.

Please refer to the following radius chart:

Download (162.06 KB)

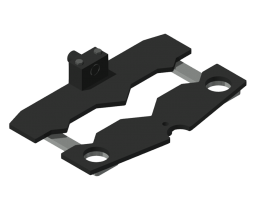

Baluster forming die 01 PP200

Die to form cold forging balusters for grills, gates, fences, handrails, etc... For other shapes or capacities, request the manufacturer.

REF: 140-16-01-00001

MAX WIDTH: 20mm

THICKNESS: 4,5,6,8 mm

DIE LENGTH: 656mm

WEIGHT: 21 Kg

Optional tooling.

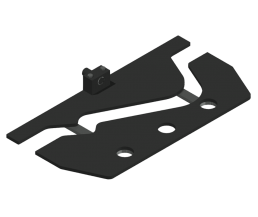

Baluster forming die 04 PP200

Die to form cold forging balusters for grills, gates, fences, handrails, etc... For other shapes or capacities, request the manufacturer.

REF:140-16-01-00004

SQUARE SIZES: 5,6,8,10,12,14,16,18mm

DIE LENGTH: 600mm

WEIGHT: 20,5 Kg

Optional tooling.

Baluster forming die 08 PP200

Die to form cold forging balusters for grills, gates, fences, handrails, etc... For other shapes or capacities, request the manufacturer.

REF:140-16-01-00008

MAX. WIDTH: 20mm

THICKNESS: 4,5,6,8mm

DIE LENGTH: 650mm

WEIGHT: 19,5 kg

Optional tooling.

Baluster forming die 09 PP200

Die to form cold forging balusters for grills, gates, fences, handrails, etc... For other shapes or capacities, request the manufacturer.

REF:140-16-01-00009

SQUARE SIZES: 5,6,8,10,12mm

DIE LENGTH: 522mm

WEIGHT: 22 Kg

Optional tooling.

Baluster forming die 10 PP200

Die to form cold forging balusters shaped parts for grills, so called “belly top railing”. For other shapes or capacities, please cosult the manufacturer.

REF:140-16-01-00010

SQUARE SIZES: 12mm

DIE LENGTH: 1165mm

WEIGHT: 50Kg

Optional tooling.

Baluster forming die 11 PP200

Die to form cold forging balusters for grills, gates, fences, handrails, etc... For other shapes or capacities, request the manufacturer.

REF:140-16-01-00011

SQUARE SIZES: 6, 8, 10, 12mm

DIE LENGTH: 760mm

WEIGHT: 32,5 Kg

Optional tooling.

Baluster forming die 20 PP200

Die to form cold forging balusters for grills, gates, fences, handrails, etc... For other shapes or capacities, request the manufacturer.

REF:140-16-01-00020

SQUARE SIZES: 12x12mm

CIRCUMFERENCE SIZE: 90mm

WEIGHT: 11 Kg

Optional tooling.

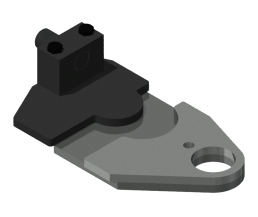

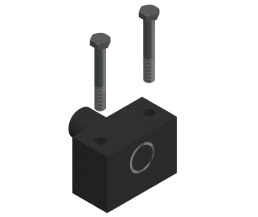

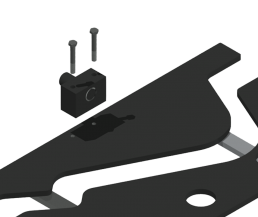

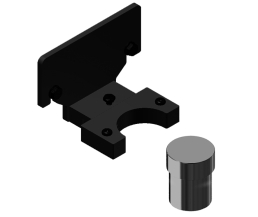

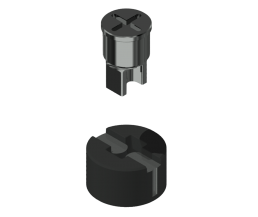

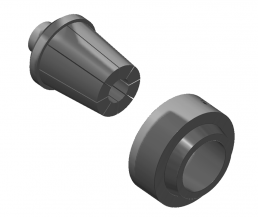

Forming die adaptor PP200

It is an exchangeable fitting device for the forming dies, suitable for each of the different baluster forming tools. It is advisable to get one in order to work with the specified dies.

REF: 140-16-01-00029

WEIGHT: 3,1kg

Optional tooling suitable for all forming dies.

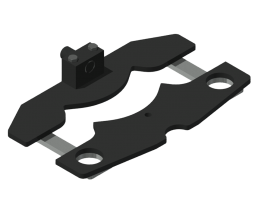

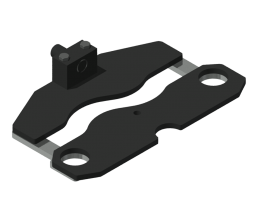

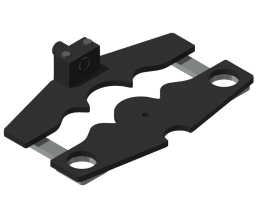

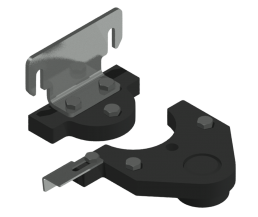

Bar clamps forming die PP200

Clamp forming die, used to manufacture the clamps used to join different forging bars with no need to get them welded.

REF:140-16-01-00028

MAX. CAPACITY: 25x5mm

WEIGHT: 9 Kg

Optional tooling.

Download (1.55 MB)

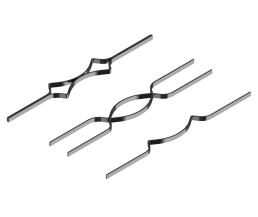

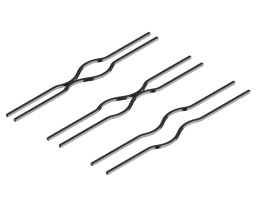

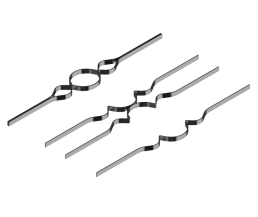

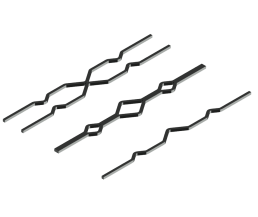

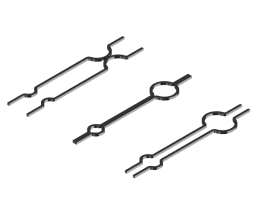

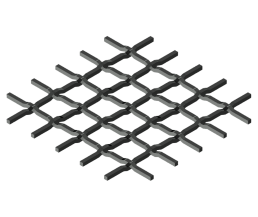

Twisted bars forming die PP200

Die to bend metal plate, flat bar or square bar to obtain a nice braid twisted effect. It’s very used to make fences and grills

For flat bars from to 6, 12 and 14mm. (For different sizes, please ask the manufacturer)

REF:140-16-01-00013

MAX CAPACITY: Square 14mm

MIN. CAPACITY: 2x40mm metal sheet

WEIGHT: 18 Kg

Optional Tooling

Download (1.59 MB)

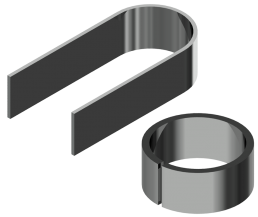

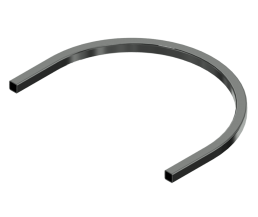

Ring forming die PP200

Die to form rings or English banister railing, used as ornamental piece in forging railings, gates, fences, etc ... for bars bonding. For other sizes and applications consult the manufacturer.

REF:140-16-01-00003

MAX. WIDTH: 50mm

THICKNESS: 6mm

OUTER SIZES: 90mm

WEIGHT: 9.3 Kg

For different sizes, please ask the manufacturer

Optional tooling.

Download (1.57 MB)

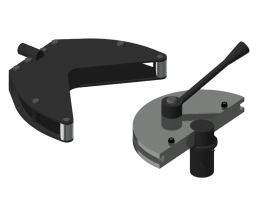

Punching die PP200

Punch-holder die, compatible with our NARGESA brand punches.

REF:140-16-01-00022

GOOSENECK: 54mm

DISTANCE FREE FOR USE: 95mm

MAXIMUM ROUND PUNCHING CAPACITY: 43mm

MAXIMUM SQUARE PUNCHING CAPACITY: 35mm

MAXIMUM RECTANGULAR PUNCHING CAPACITY: 20X34mm

MAXIMUM OVAL PUNCHING CAPACITY: 21X40mm

It will always depend on the thickness to be pierced.

WEIGHT: 52Kg

Optional tooling.

Round, square, oval and rectangular punches and dies PP200

At Nargesa we own a wide catalog for punches and dies of all kinds. If the size the cuetomer needs is not in the list, we manufacture it. In the PDF file you will be able to see all kinds and sizes we have.

Optional tooling

Download (888.51 KB)

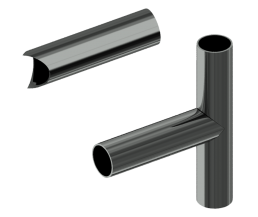

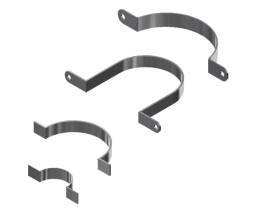

Pipe notching tool PP200

Dies for notching pipes from Ø16 to a Ø50mm. It crops the pipe end so it could be joined perpendicularly to another pipe. In the PDF file you will be able to see all kinds and sizes we have

Optional tooling.

Download (508.27 KB)

Rounding corner tool PP200

Die to get metal sheet corners rounded at different radius. In the PDF file you will be able to see all kinds and sizes we have

Optional tooling.

Download (403.02 KB)

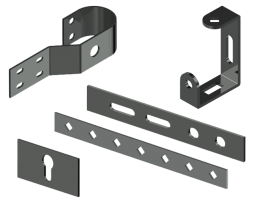

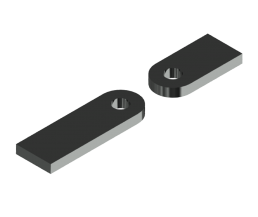

Metal tabs forming tool PP200

Tool to fabricate all kinds of tabs, with or without perforation, straight or rounded... they are very used as clamps, handles etc. Starting from a metal strip, there will be obtained one piece of the desired length at every stroke. In the PDF file you will be able to see all kinds and sizes we have

Optional tooling.

Download (485.83 KB)

Clamp forming die PP200

Die to form all kinds of clamps. This tooling is manufactured according to the user’s needs thus it is required to have a technical drawing or a sample piece.

REF:140-16-01-00024

MAX. CAPACITY: 100x4mm

Non-standard optional tooling.

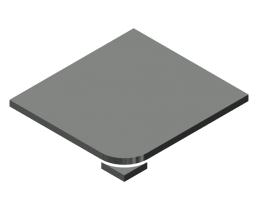

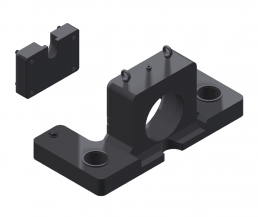

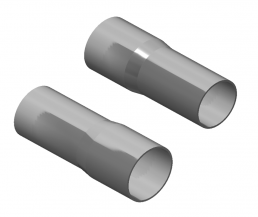

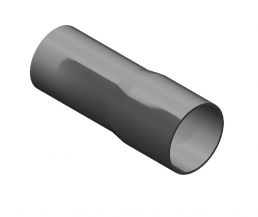

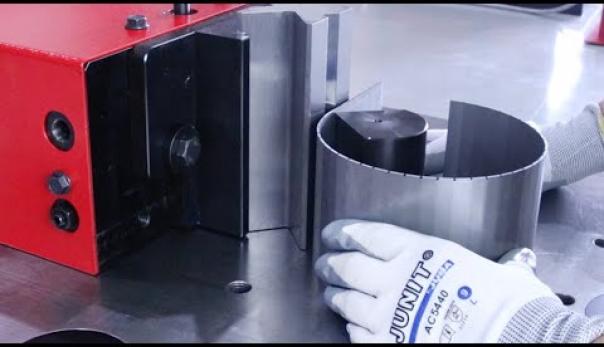

Tool to shape pipe ends PP200

Basic die to modify the ends of the tubes for their assembly. You can make all kinds of shapes and flaps accoprding to the customer needs. For special forms consult the manufacturer.

REF: 140-16-01-00016

WEIGHT: 110 Kg approx.

Optional tooling.

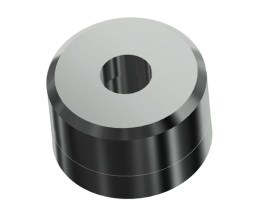

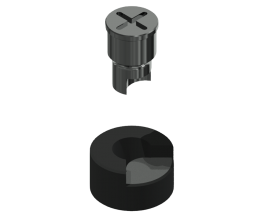

Diameter reduction tools for PP200

Composed by the Reduction cone, Reducing clamp holder to reduce tube and the reduction clamp.

This accessory is adapted to the Tooling to shape pipe ends, to perform the operation of reducing the ends of the tubes, for its coupling.

We can find the different sizes in the following PDF file:

Download (481.14 KB)

Diameter expansion tools for PP200

Composed by the Clamp Holder to Expand, Expansion Mandrel and the Expander Clamp.

This accessory is adapted to the Tooling to shape pipe ends, to perform the operation of expanding the ends of the tubes, for its coupling

We can find the different sizes in the following PDF file:

Download (385.09 KB)

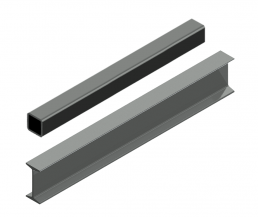

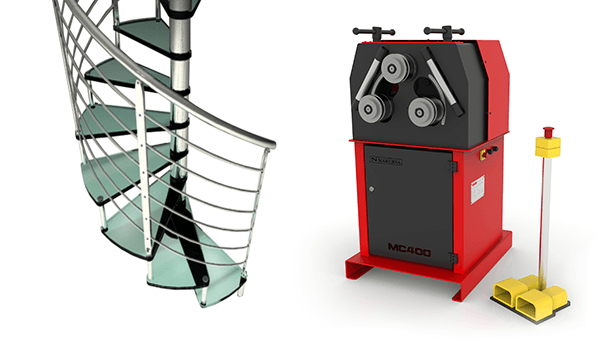

Bending tool for big radius PP200

Die to form curves in flat bars, pipes, bars or profiles at big radius. It’s perfect for bending small series or special parts without requiring a specific custom mold.

REF: 140-16-01-00006

MAXIMUM BAR CAPACITY: 40mm or 1 1/2"

MAXIMUM PIPE CAPACITY: 80x80 mm or 3"

MINIMUM DIEMETER: 300mm.

MAXIMUM DIAMETER: there is no maximum.

Optional tooling.

Die to straighten out profiles PP200

Tool used to bend straight profiles or parts. It is adjustable to different capacities according to the profiles.

REF:140-16-01-00017

MAXIMUM CAPACITY: H 150mm

WEIGHT: 72Kg.

Optional tooling.

Included accesories for Horizontal Hydraulic Press Brake PP200CNC

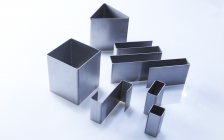

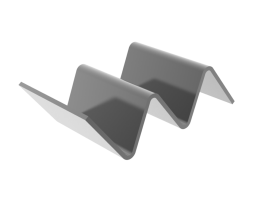

FOLDING DIE AT 161 MM. V 16,22,35,50 MM. PP200

Folding or bending die up to 161mm with 4 openings (16, 22, 35, 50mm) and a punch of 80º. This multi-V die allows 1mm up to 8mm sheet to be folded. The 70mm outer die ameter punch allows to make completely closed shapes to a minimum of 75mm inner wing.

Folding punch ref.: 131-16-01-00041 · P.70.80.R1.5

Folding die ref.: 125-16-01-00006

V 16: Sheet from 1 to 3mm · M.460.R/16

V 22: Sheet from 2 to 4mm · M.460.R/22

V 35: Sheet from 3 to 6mm · M.460.R/35

V 50: Sheet from 4 to 8mm · M.460.R/50

MAX. FOLDING LENGTH: 161mm

MAX. FOLDING THICKNESS: 8mm

Standard tooling provided along with the machine

Download (424.88 KB)

Download (1.82 MB)

+ Info for Horizontal Hydraulic Press Brake PP200CNC

ESA S625 CONTROL PANEL

Nargesa horizontal press brakes have a 7” color touch screen control, very intuitive and easy to handle, with the latest 4.0 technology and a more comfortable and accurate regulation.

We only have to introduce the material, the thickness, the bending angle, choose the punch and the die from the library and the control will program the rest of the parameters automatically.

These are some of the most relevant features of this control system.

- Stores up to 10,000 programs.

- Up to 50 different angles on the same piece can be programmed.

- Dimensions may be programmed in inches or millimetres.

- A library of available dies with the possibility of programming new ones.

- Library of materials and thicknesses available with the possibility of programming new options.

- The CNC can be supplied in more than 20 different languages.

- Automatic control of the angle to fold, in degrees.

- 9.8mm/s working speed and 35mm/s reversing speed.

- Manual or automatic operation.

- Automatic elastic recovery correction (springback).

- Piece counter.

- 4.0 Technology.

- On-screen alarm diagnostics.

- Preventive maintenance warning.

- Can be remotely connected by the manufacturer without having to travel to the machine site.

- 7” colour touch-screen with 800 x 480 resolution.

- 128 MB silicon disk.

- 2 analogue inputs, 12 bit resolution.

- 16 digital inputs (24 Vdc).

- 16 digital outputs (24 Vcc, 0.7 A max.) Protected against overloads and short circuits.

- 1 RS232 serial port.

- 1 CAN port with 9 D-Sub F connector contacts.

- 24 Vdc power source.

- 1 USB port.

- 1 Ethernet port.

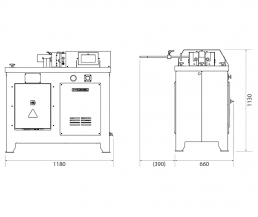

Dimensions of the machine Horizontal Hydraulic Press Brake PP200CNC

Characteristics of the packaging Horizontal Hydraulic Press Brake PP200CNC

Nº Pallets: 1.

Width: 930 mm.

Length: 1300 mm.

Height: 1500 mm.

Volume: 1,81 m3

Nett weight: 665 Kg.

Gross Weight: 712 Kg.

Tariff Item Code: 84622210

Other features:

- Palletized bench to move the machine easily to the working site or storage.

- The machine is delivered completely mounted.

- Packaging with wooden pallet and 3-layered cardboard, suitable for sea freight.

- Optional: Complete wooden packaging NIMF15.

Uses of the machine Horizontal Hydraulic Press Brake PP200CNC

There are multiple uses for the Horizontal Bending Press PP200CNC Nargesa. The large number of tools that complement it allow several operations in different materials and in different types of profiles. Bending and folding flat bars with horizontal press will enable the manufacturing of completely closed pieces that would be difficult to obtain by using other machines. Straightening and bending large profiles to conform bus chassis, prototypes with complicated curves and bends, straightening faulty profiles ... Cutting flat bars or metal sheets a lot faster than any other saw or cutting machine. Punching, boring, drilling or punching plates to make perforations on fences, doors, windows and other parts. Cutting and shaping are other features of this versatile forming press for manufacturing flanges and clamps for fastening pipes. Flaring tube or pipe for assembly and subsequent welding to produce exhaust pipes, water pump distributors, metal furniture, railings tube... Widening and reducing the pipe ends permit joining different pipes to make berths, chairs, irrigation systems, tents, greenhouses etc... Folding and bending solid rods will enable the user to manufacture all kinds hooks, chain links and also form balusters out of square or round bars, tubes for the manufacturing of parts for cold forging, railings, fences, gates, doors, railings... Making hinges is another widely used application in this type of hydraulic press. As you can see, the uses of Hydraulic Horizontal Bending Press Nargesa PP200CNC are really limitless.